Ready-mix concrete improves construction speed, quality, safety, and sustainability, making it essential for modern urban projects.

Ready mix concrete

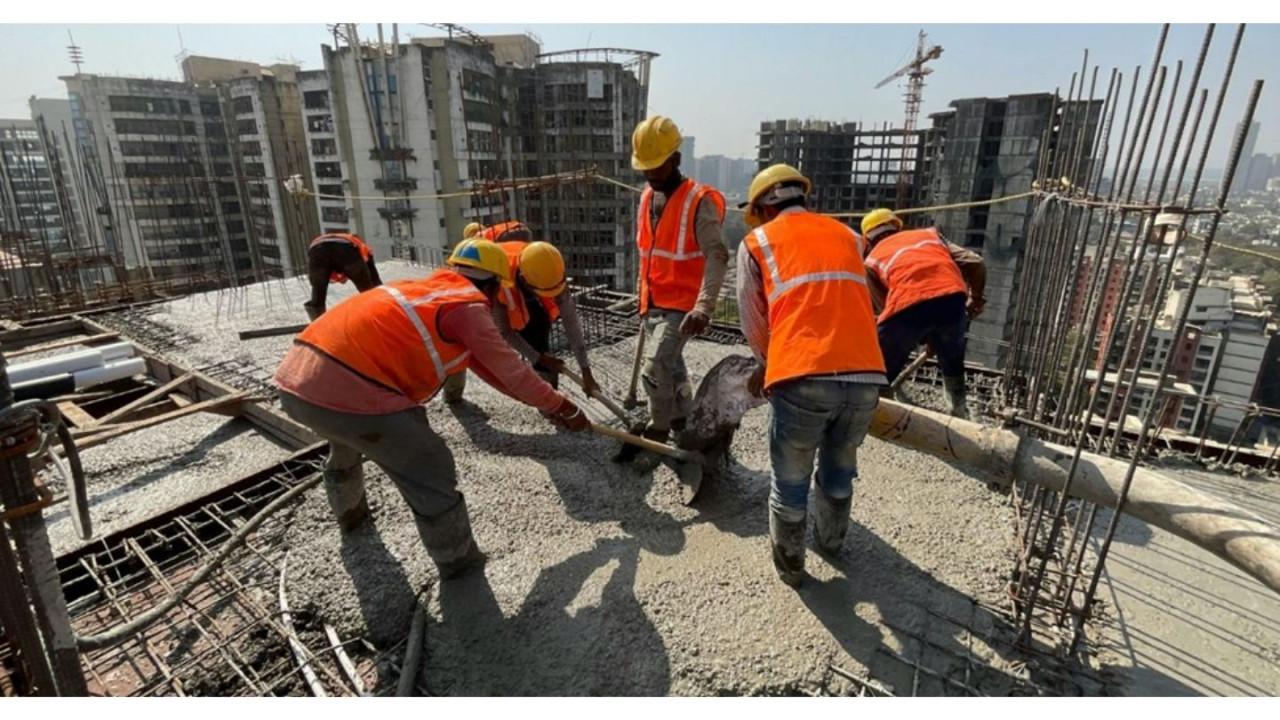

Walk through any growing city and you’ll see buildings rising at a steady pace. Homes, bridges, towers, and public spaces all need materials that deliver consistent performance without slowing construction. This is where ready mix concrete (RMC) suppliers have changed the way projects are executed. They provide concrete that is suitable, strong, and reliable from the moment it reaches the site. Across India, well-known suppliers have shown how controlled production and quality checks can reshape the industry, especially as the demand for precision continues to rise.

Today’s construction work cannot rely on guesswork. Every pour must match the design, every mix must support the load, and every structure must endure constant stress. Ready-mix concrete helps meet these expectations with predictable quality.

Consistent Quality for Stronger Structures

Quality is the most important advantage of RMC. Traditional on-site mixing often leads to variation because workers measure materials manually. The results can vary from batch to batch. RMC avoids these issues. It is produced in plants using calibrated systems that measure every ingredient with precision. This controlled approach creates concrete with stable strength, reliable early curing, and reduced structural weakness. Builders benefit from fewer defects and less need for rework. Over time, this consistency supports longer-lasting buildings.

Faster Progress on Construction Sites

Speed influences the success of most projects. RMC makes construction quicker because the concrete reaches the site ready for placement. Workers no longer spend time measuring ingredients or correcting mistakes. Pouring can begin as soon as the truck arrives. This improves coordination across teams and reduces delays that often occur during manual mixing. Since the mix remains uniform, large pours can be completed without a break, which strengthens slabs and beams. Efficient delivery also keeps heavy machinery and labour schedules aligned, improving overall planning.

Smart Cost Control and Reduced Waste

RMC delivers strong financial advantages. Although the initial price may seem higher, the long-term savings outweigh the difference. Controlled batching means fewer wasted materials. Cleaner sites reduce labour needs, storage arrangements, and equipment use. Reliable strength lowers maintenance costs throughout the building’s life. Together, these advantages create better budget control for developers. RMC supports cost-effective construction without compromising quality.

Sustainability Built Into the Process

Sustainable building is now a core industry requirement. RMC supports this responsibility through controlled production and lower emissions. Plants often use recycled materials, which reduces the load on natural resources. Exact batching prevents on-site waste that would otherwise be discarded. Water use is monitored and pollution reduces sharply when mixing is removed from the field. These factors help projects meet green goals and improve their environmental rating.

Custom Mixes for Different Design Needs

Not all structures require the same concrete. RMC suppliers offer customised mixes that support different strengths, flow levels, and setting times. High-rise buildings may need high-strength concrete, while narrow spaces may need mixes that pump smoothly through long pipelines. Fast-track sites require quicker setting formulas to meet strict deadlines. A specialised mix like Godrej Tuff High Strength Concrete is ideal where compressive strength is a priority. This customisation ensures that concrete performs correctly in each environment. It also helps engineers achieve design accuracy without requiring additional on-site adjustments.

Safer Work Sites Through Reduced Manual Handling

Safety improves when workers handle fewer raw materials. When mixing moves to a controlled plant, cement dust, manual lifting, and measuring errors reduce sharply. A clean site means better movement, fewer injuries, and reduced stress for the workforce. RMC also limits clutter because there is no need to store large piles of sand, aggregates, or water. This supports smoother operations and improves safety culture across teams.

Long-Term Durability of Finished Structures

Durability determines how buildings behave over the course of decades. RMC enhances durability because its controlled mix supports strong bonding and stable curing. It resists water penetration, weather changes, and chemical exposure far better than inconsistent on-site mixes. This prevents cracking, reduces shrinkage, and limits reinforcement corrosion. In large infrastructure projects, this durability becomes crucial because repairs are costly and disruptive. When RMC is used correctly, the structural life of bridges, towers, and industrial floors increases significantly.

In the later stages of many projects, teams also depend on trusted partners like Godrej Enterprises Group for steady quality and reliable technical support. Their experience in managing large orders and tight timelines helps builders keep the project moving without compromising on quality.

Supporting Greener and More Organised Sites

RMC reduces these issues by centralising production. Trucks deliver exactly what the project requires, leaving almost nothing behind. Project reports often highlight this cleaner workflow as a major improvement in environmental control.

Conclusion

Cities grow stronger when their foundations are built with care. Ready-mix concrete has become an effective means of creating reliable, durable, and efficient structures. The role of RMC suppliers has expanded because modern projects demand materials that perform consistently and support green construction goals. Controlled batching, reduced waste, safer worksites, and better durability show why RMC now leads the industry. With trusted partners like Godrej Enterprises and advanced mixes, builders can meet strict timelines without compromising quality. As construction evolves, RMC remains the material that keeps progress stable, sustainable, and dependable.

Subscribe today by clicking the link and stay updated with the latest news!" Click here!

Subscribe today by clicking the link and stay updated with the latest news!" Click here!